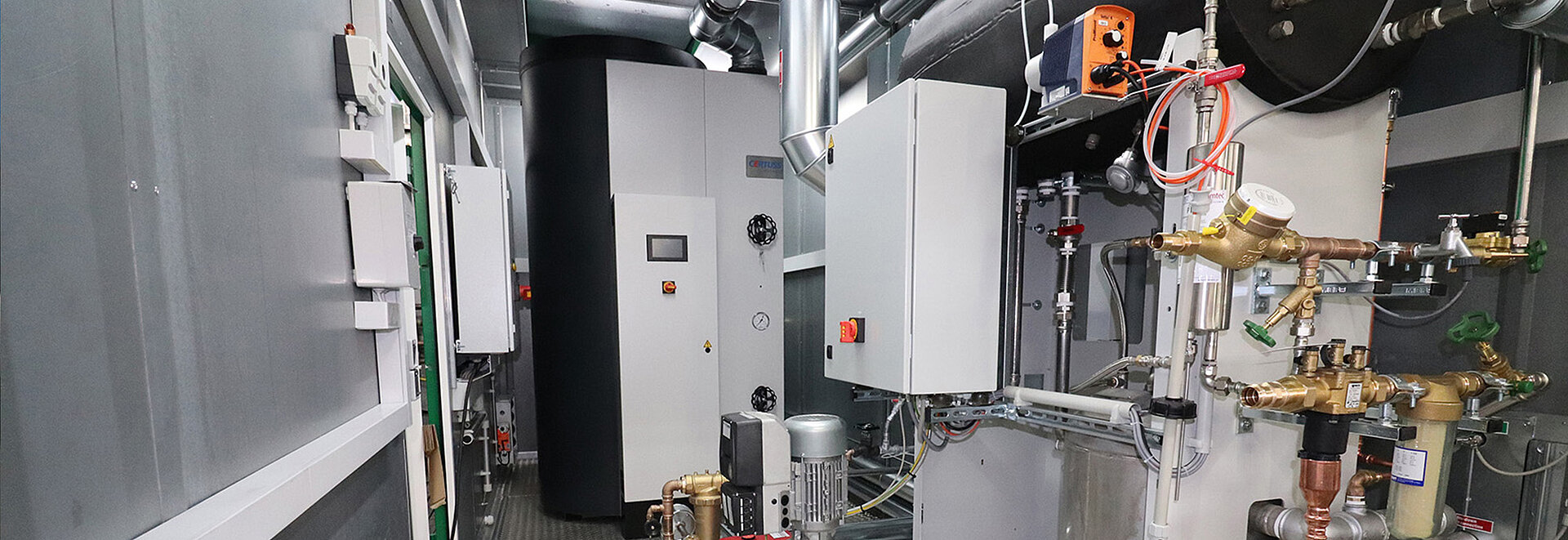

Combustion air preheating

Thanks to CERTUSS combustion air preheating, a combustion-specific degree of efficiency that is unusually high for steam generators is achieved.

The air insulation with heat recycling and preheated combustion air differ from all other systems and designs. Clean combustion air is drawn in from above. This air counteracts trapped heat from the combustion chamber.

- The air circulates through a 3-chamber system comprised of a main combustion chamber, inner insulation and outer insulation. Emission losses are minimized by the 3-fold air insulation.

- The 3-fold combustion air preheating of CERTUSS steam boilers achieves an especially high degree of efficiency of 94% in comparison to other steam generators.

Heat recycling with flue gas heat exchangers

- The maximum degree of efficiency can be achieved through additional heat recycling from the flue gas. All natural gas-, oil- and combination-combustion steam generators from CERTUSS can be equipped with powerful economizers upon request.

- With a flue gas heat exchanger (economizer), the degree of efficiency increases to 98%. If a second heat exchanger is used, this is increased to 102%.

- Further possibilities for increasing efficiency with flue gas heat exchangers are available on request.